The corrosion of reinforcement in deteriorating concrete structures is widely encountered, posing a major limitation on their durability. Premature corrosion occurs primarily due to crack formation in the concrete cover. Larger cracks as well as a network of finer cracks allow water, oxygen, chloride and other aggressive corroding substances to permeate the concrete matrix reaching the reinforcement. Other forms of deterioration include frost action and alkali-silica reactions – although less frequent, are no less damaging. In anticipation of such damage, costly maintenance and repair measures are often undertaken.

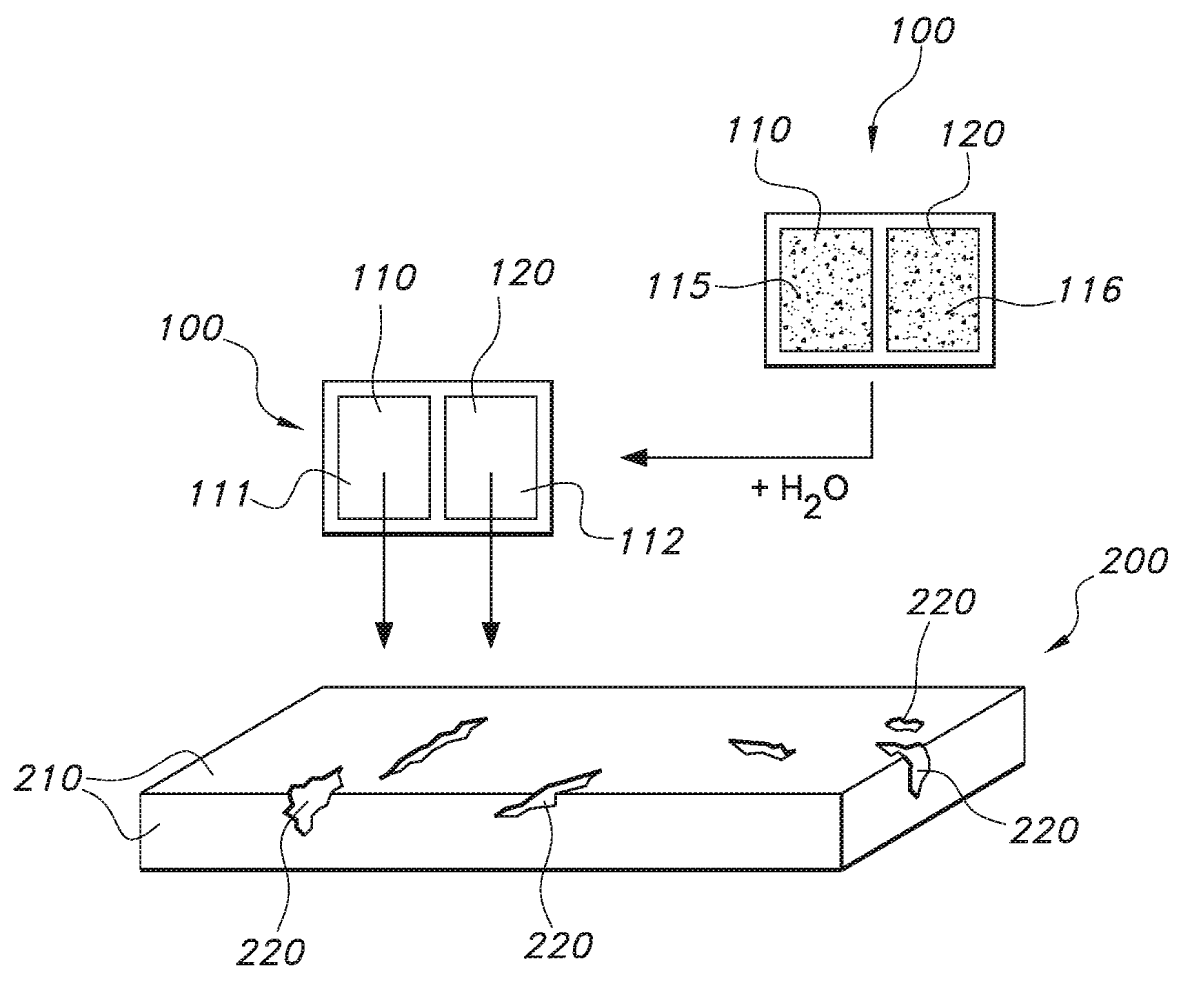

In August 2019, Green-Basilisk B.V. was granted European patent EP2996999B1 designating the UK, titled Bio-based repair method for concrete. The patent disclosed a process for the bio-based repair of a concrete element (200) having an element surface (210) with cavities (220). The process comprises applying a first liquid (111) with a first composition and a second liquid (112) with a second composition to the element surface to provide a combined product to the cavities. The first and second compositions are selected to provide gel formation in the cavities after the application of the first and second liquids to the element surface. The first and second liquids comprise water. The compositions are also selected to provide bacterial material, a calcium source, and a nutrient for bacteria in the cavities after the application of the first and second liquids to the element surface. The first liquid at least comprises a sodium silicate in an amount of 0.5 wt.% to 20.0 wt.%, the second liquid at least comprises the calcium source, and the nutrient comprises a nitrate compound, a yeast extract and one or more of a lactate and a gluconate.

The first liquid may have a pH of at least 11, and the second liquid may include calcium nitrate in an amount of 10wt.% to 75wt.%, preferably 25wt.% to 55wt.%. The second liquid – comprising the calcium source, may be applied to the element surface after the first liquid – comprising the sodium silicate. The first and second liquids may be applied within 0.5 hours of each other. Optionally, the molar ratio between the silicate and calcium may be in the range of 0.05 to 5.0. The calcium source may build a new structure in the cavity i.e. repair a crack, through the formation of calcium structures, including calcium phosphate and/or carbonate in an alkaline medium – provided by the sodium silicate.

The combination of building material, bacteria, and the nutrient for the bacteria incorporated in a concrete structure, may perform the autonomous repair of cracks when activated by water. The bacterium may repair cracks by building the calcium structures in the alkaline medium. The bacterial material may consist of a bacterium, a lyophilized bacterium or a bacterial spore of a bacterium, and may be selected from the genera consisting of Planococcus, Bacillus and Sporosarcina. The liquids may be provided in a kit of parts (100) including a first container (110) and a second container (120). In one embodiment, the first liquid may comprise bacterial spores, sodium gluconate and sodium silicate, and the second liquid may comprise bacterial spores and calcium nitrate.

The patent further discloses experiments performed on concrete structures using the bacteria-based repair system. The results found that the bacteria-based repair system led to improved properties in porous network concrete beams – after 28 days, the cracks remained sealed with no leaking. A newly formed mineral observed along the crack walls was characterised as a Ca-based mineral using ESEM. These results were consistent with other trials in which the lack of calcium in the composition of the repair system led to cracks that were only partially sealed – water permeability only decreased to 32%. With extra calcium added, however, the cracks were fully sealed resulting in zero permeability.

Read the full patent here.

This article first appeared in the April 2020 issue of Materials World, the member magazine of the Institute of Materials, Minerals and Mining.

The Patent Eye blog offers a glimpse into the future by showcasing newly granted patents. Join us as we explore the latest innovations shaping our world.

The Patent Eye blog is made available by Alphabet Intellectual Property for informational purposes, in particular, sharing of newly patented technology from granted and published patents available in the public domain. It is not meant to convey legal position on behalf of any client, nor is it intended to convey specific legal advice.

Craving intellectual stimulus? Peer into the insights brought to you by The Patent Eye and explore our latest articles.