Rechargeable batteries are typically lithium-ion (Li-ion) based and suitable for powering small devices. The charge capacity of a Li-ion battery is directly proportional to its weight so Li-ion batteries suitable for higher wattage devices are often heavier. In comparison, rechargeable batteries based on nickel-ion (Ni-ion), zinc-ion (Zn-ion) and aluminium-ion (Al-ion) batteries have higher energy densities and can be charged at a relatively faster rate.

In February 2020, DST Innovations Ltd was granted UK patent GB2553128 titled Rechargeable power cells which disclosed a method of manufacturing a rechargeable power device. The method comprises forming a plurality of supercapacitors (2) and at least one rechargeable battery (3) by printing – and coupling them by means of control electronics. The supercapacitors are arranged in a substantially planar array such that physical gaps are present between each supercapacitor in the array.

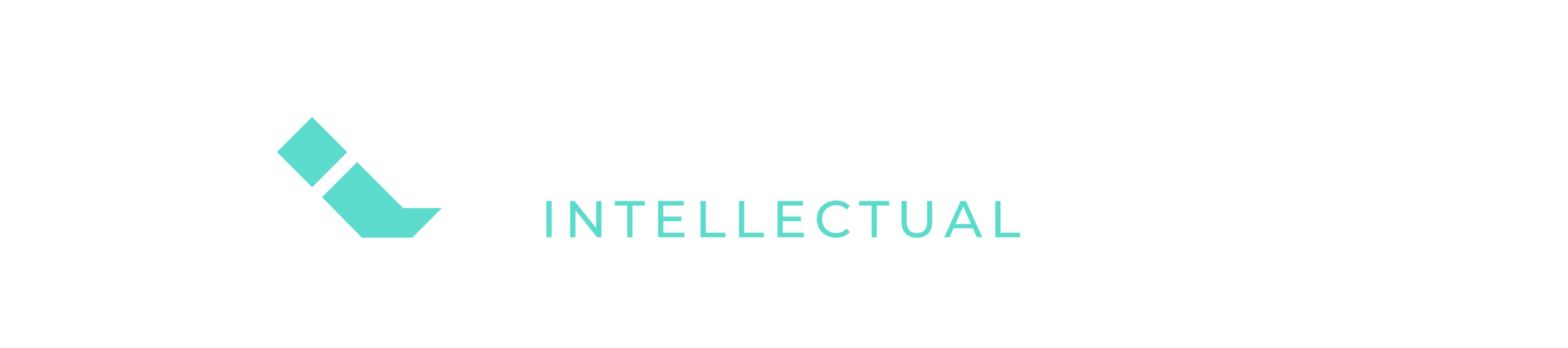

In the illustrated example, energy is rapidly passed in a power cell (1) from an input power source (4) – powered from an external power source, via input power source control electronics (5) to the supercapacitors – coupled to supercapacitor control electronics (8). Energy is stored in the supercapacitors before being passed onto charge management electronics (6) that connect both output management electronics (7) and the rechargeable battery. The rechargeable battery is also connected to the output management electronics and may be Ni-ion, Zn-ion, or Al-ion based – capable of taking charge from the supercapacitors at a high rate.

The supercapacitors may be charged from a power supply at a substantially faster rate than a traditional rechargeable battery, the charging time of the power cell thereby significantly reduced. The energy stored in the supercapacitors may be used directly by the output management electronics to power or recharge an electronic device or to charge the rechargeable battery, providing spare capacity for the supercapacitors to store more charge. The rechargeable battery may power an electronic device while being recharged by the supercapacitor simultaneously. For higher wattage devices, the rechargeable battery can even be used to charge the supercapacitors.

Energy stored in the supercapacitors can be used to charge the rechargeable battery slowly, greatly reducing the possibility of damaging it. Optionally, the input power source control electronics may enable charging of the supercapacitors rapidly while charging the rechargeable battery at the same time. When the external power source is disconnected, the supercapacitors may transfer charge to the rechargeable battery for long-term storage.

The power cell may comprise an assembly of multiple layers of active materials, printed using techniques including screen printing. The patent further discloses how the supercapacitors and rechargeable batteries may be formed. Exemplary embodiments described include a Zn-ion rechargeable battery, and a printed supercapacitor including an electrode paste comprising V2O5 and Ni(OH)2 that is printed onto a TiN coated steel substrate.

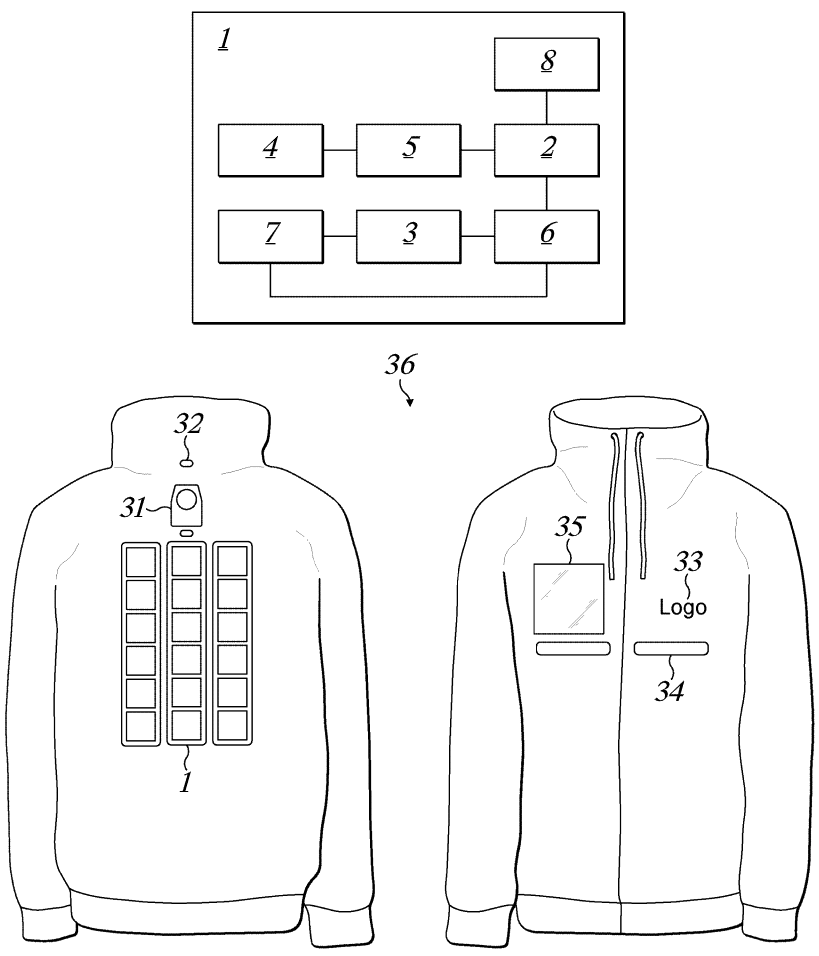

The rechargeable battery may be a roll-to-roll screen printed battery, fully customisable to any shape or size. The array of supercapacitors may provide increased flexibility for the device, relative to a single supercapacitor, due to the presence of gaps between each supercapacitor in the array.

Exemplary applications include use of the power cell in consumer electronic devices or a series of power cells for larger scale equipment, such as in automotive applications. The supercapacitors and rechargeable batteries may be split into thin films spread over a wide area, or form a multilayer device incorporating photovoltaic cells for harvesting energy stored in the power cell.

The rechargeable power device may be applied to wearable technology including smart watches, or garments (36) where the device is sandwiched between layers of fabric. A programmable microcomputer (31) may handle input and/or output from sensors (32) – such as motion sensors, passing data to visual and/or audible devices – such as an electroluminescent logo (33), a heart monitor (34) or a display screen (35).

This article first appeared in the May 2020 issue of Materials World, the member magazine of the Institute of Materials, Minerals and Mining.